Time being limited and linear, it’s taken me over a month to get around to tackling the twenty-inch reversible grill reseasoning project.

For reference, check out parts one and two wherein I presented my options to deal with the pitting that was destroying the five-year-old seasoned surface of my Saturday morning pancake flattop and tried the least aggressive way I had read about, soaking in vinegar, to strip the seasoning. Spoiler alert, vinegar didn’t work.

A couple days ago I went to the store and picked up a can of oven cleaner, a pack of abrasive dish cleaning pads, a roll of industrial strength paper towel, and a pack of steel brush wheels for my power drill.

What I’ve read online (since I’ve never stripped a pan this way before) was that spray on oven cleaner is an agressive chemical approach to degrading the seasoning of the pan enough that you can pretty much just wipe it off.

It wasn’t quite that simple, of course.

The instructions I had read told me to coat the surface in oven cleaner, wrap in a plastic bag, and wait twenty-four hours.

Tick. Tick. Tick.

Furstratingly, a day later, I had a pan with some very clean, but still very firmly attached, seasoning.

Back to the drawing board.

Yesterday afternoon I rinsed off the pan, and switched over to the drill and wire brush method. Forty-five minutes of shoulder aching, noisy, smelly, whirring away on the pan, I had stipped about half of the top surface down to bare iron.

To be honest, I’ve not been too worried about the edges or the reverse side. The bottom of this pan is a ridged grill pan that I think we’ve used less than five times since we bought this piece. It’s not that it isn’t useful, it’s just that this grill is pretty much my dedicated pancake pan and the smooth side gets used weekly and so consequently the smooth side is the side that I care about.

But even given that I only cared about the top half of the pan, a day plus forty five minutes of neighbourly-annoying outdoor cast iron maintenance had only got me part way to what I’d accomplished pretty much passively when I reseasoned this years ago by the self-cleaning oven method. That method, of course, has it’s risks not the least of which is the risk of the pan cracking in extreme heat, but with a crick in my back and a small bit of flaking seasoning embedded under my bleeding thumbnail (did I mention that part?) I was starting to reconsider the risk versus reward calculation.

Then I had a bit of an idea … mostly because I was tired and it was starting to get dark out

I lightly burred down the rest of the still-seasoned parts of the cooking surface with the steel wire brush, then resprayed with oven cleaner before stuffing it back in the bag and stowing it once again for an overnight.

This morning the results of the combined method had seemed to have paid off respectably well.

Over the pan where I had scuffed the surface of the seasoning, the chemical oven cleaner had been able to get under and into the old seasoning. It was able to do the job I had expected a day earlier. The bulk of the old seasoning flaked off and easily washed away with a little bit of light scouring from a dish pad.

I was able to grind the remaining stubborn specks off with the drill setup, wash it down really well, dry it up, and …

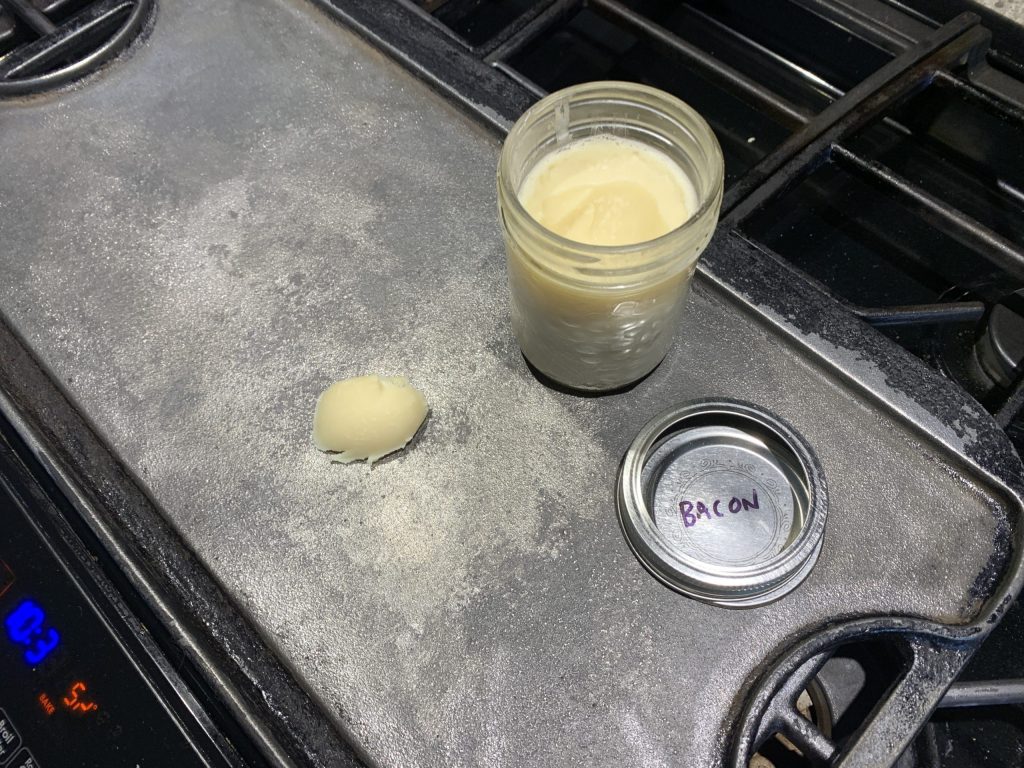

… as I write this post the pan is in the oven baking on a first coat of bacon grease seasoning.

I’ll spend the day doing multiple coats of a new seasoning layer, getting it back up to a surface that I can attempt some pancakes on in the coming week, and of course, report back with how it all turned out!

And hopefully part four is the part where I tell you how great it all turned out … and not me resorting to the self-cleaning oven again.

You must be logged in to post a comment.